In this blog, explore the world of Stainless Steel manufacturing in India, covering the complete process, key industry players, and tips to choose the right Stainless Steel plant manufacturer for your business needs.

Stainless Steel manufacturing in India acts as one of the essential founding elements that support Indian industrial growth. This important economic sector provides vital support to the development of construction and automotive as well as infrastructure and engineering industries.

Today India ranks as the 2nd largest producer of Steel and its steel industry heavily contributes to economic growth along with job creation and international exports.

Key Takeaways

A metal manufacturing company in India uses iron ore and coal to generate different steel products. The manufacturing company produces stainless steel and carbon steel as well as alloy steel which serve different sectors of use.

A steel production company makes its products range from TMT bars to automotive coils. India has experienced quick expansion of its stainless-steel manufacturing sector. Customers buy the company’s products because they provide both outstanding strength characteristics and long-lasting durability alongside corrosion resistance properties.

Stainless steel displays perfect attributes that suit both architecture and transportation needs and heavy machinery applications.

The contribution of steel manufacturing plants in India is essential to support growing infrastructure needs.

These plants operate in various parts of the country, with strong activity in Maharashtra. The state is home to top steel manufacturers in Maharashtra and has evolved into a strategic manufacturing hub.

Here’s a step-by-step look at how steel is made and the role of major players in the industry:

The production sequence starts with extracting iron ore together with coal and limestone from mining operations since these materials serve as the base for steel creation.

The blast furnace combines processed raw materials to produce molten iron which serves as the base of steel production.

A combination of molten iron and scrap steel goes through a refinement process in basic oxygen furnaces together with electric arc furnaces to achieve high-quality steel.

The manufacturing process ends with steel production through billets, blooms or slabs casting. The semi-finished shapes have reached a state where additional forming operations can commence.

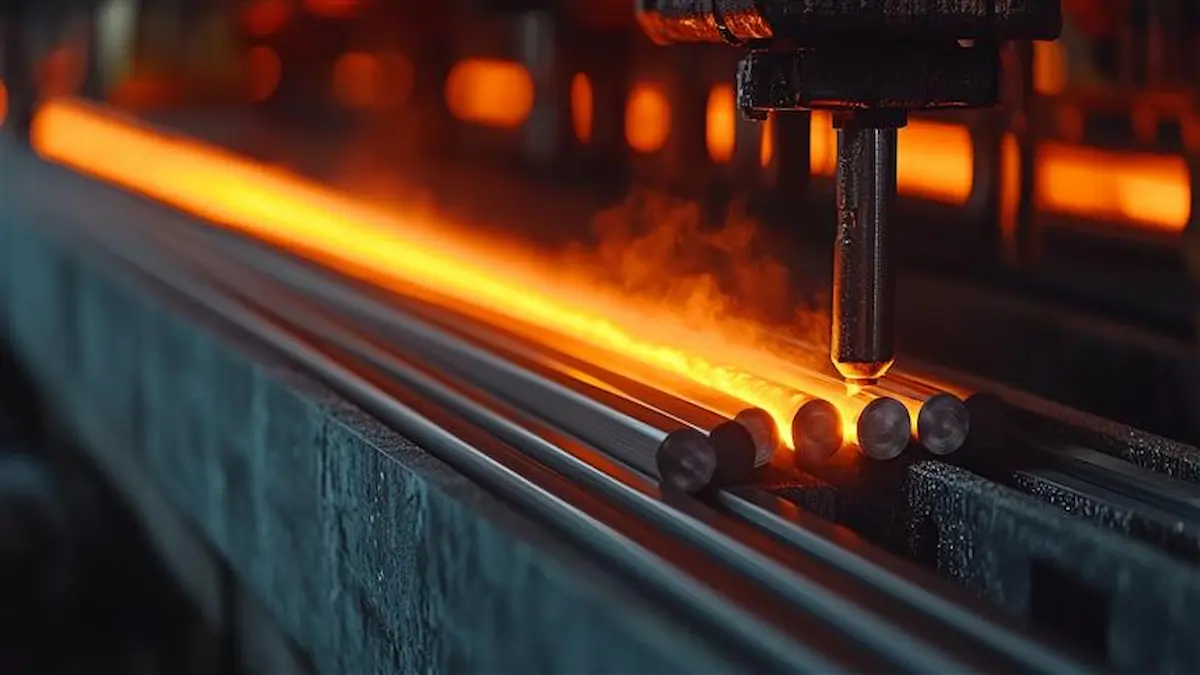

Using rolling mills, these semi-finished products are shaped into finished goods such as rods, bars, sheets, and coils.

Every batch is tested and finished to meet industrial and customer standards.

Leading steel manufacturing plants in India now use smart technologies like automation and AI to improve efficiency and accuracy.

The state is a strong base for the steel sector. Steel manufacturers in Maharashtra benefit from robust transport, skilled labor, and access to raw materials. Steel manufacturers in Mumbai in particular support a variety of industries with both bulk and custom orders.

The stainless steel industry in India supports sectors where hygiene, corrosion resistance, and design are important. This includes food processing, health care, railways, and energy.

The steel plant manufacturer’s also offers tailored products and services. Businesses need custom sizes, grades, and finishes. One of the leading steel plants in Maharashtra has the capability for flexible manufacturing to address these requirements.

This is why our steel plant will be your preferred pick for your next steel requirement:

Working with an experienced steel plant manufacturer ensures you get top-quality material that meets both local and global standards.

This blog includes all the important steps associated with the buyer journey. Initially we provided an overview of the value of steel manufacturing in India which was succeeded by a comprehensive analysis of the production process and its regional advantages.

You appreciate the value of steel manufacturing plants in India, the genesis of the stainless steel industry in India, and the advantages of dealing with credible steel plants in Maharashtra and Mumbai.

We focus on technology and quality customer service, which allows us to provide one of the most dependable metal manufacturing partnerships in the country.

The top choice for steel plants in Maharashtra is Mukand. Mukand launched its industrial production activities in 1937 with a focus on alloys and stainless-steel long products together with industrial machinery. With plants in Maharashtra and Karnataka, Mukand serves the automotive, construction, and engineering sectors with more than 400 grades of steel.

Reach out to our engineers today at enquiry@mukand.com for a personalized project consultation, detailed quote, or to discuss your requirements. Join hands with a reputable steel manufacturer today with Mukand and experience the quality and reliability that serves your company.